Food Waste Services

Providing Nationwide Service

in Food Waste Removal

ReConserve® helps leading food manufacturers and small to medium size food companies nationwide with sanitary and efficient removal of breads, cakes, candies, chips, cookies, crackers, doughs, flours, pastas, snack foods, tortillas, pizzas, nuts, cereal grains and related food by-products. This important service frees these companies to focus on their business — manufacturing quality food products.

We also help manufacturers work toward a reduced landfill objective by providing dependable custom designed bulk removal systems and reliable service assuring the food waste is fully recycled.

Our plants utilize the ReConserve process which takes food waste, separates out non-edible material, then mixes, grinds and dries the mixture into DBP®, our brand of dried bakery product. DBP® is a high-energy, nutrient dense, highly palatable dried component for livestock feed with a greater nutrient value than corn.

ReConserve Benefits:

Guaranteed Brand Identity Protection by total destruction of branded product

Certificate of Destruction for rejected/outdated product

Detailed Monthly Reports of recycled by-products

Integrated Scale Systems for tracking by-product waste streams

Professionally Engineered Systems for the highest levels of efficiency and safety

Washable Components to ensure the highest level of sanitation

More Experience than any company in the industry

State-Of-The-Art Technology For

State-Of-The-Art Service

ReConserve has earned a reputation for developing advanced food waste removal technology through careful, customer-focused planning and design along with professional engineering from start to finish.

We developed new technologies and introduced bulk loading systems to meet the needs of higher speed and greater volume operations. Many of our equipment installations incorporate cutting edge technology such as integrated scale systems and automated notification capabilities.

ReConserve meets with each client to thoroughly review manufacturing processes, waste material volume,

current removal practices, and available space. Based on this review, ReConserve custom designs the most efficient system to meet the specific needs and circumstances, addressing the highest levels of safety and sanitation, meeting and exceeding OSHA guidelines, while minimizing the client’s labor requirements.

We closely monitor the installation process to eliminate interruptions to our client’s production output. After installation, we conduct periodic reviews to ensure all equipment is maintained to meet state and local regulations and guarantee total destruction of our client’s branded product.

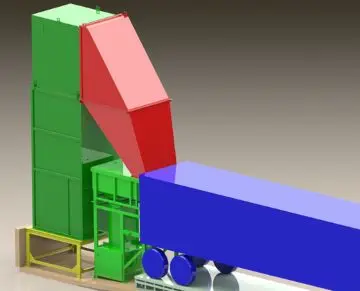

ReConserve offers several bulk loading system options:

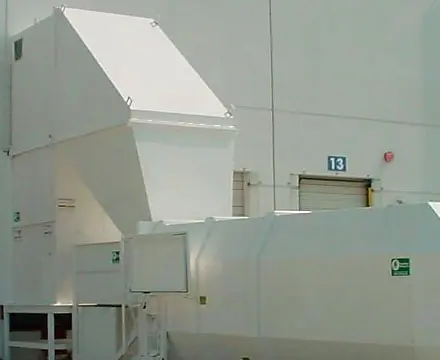

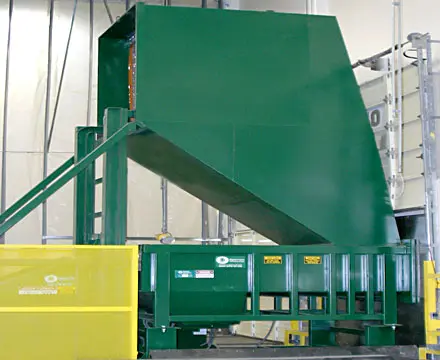

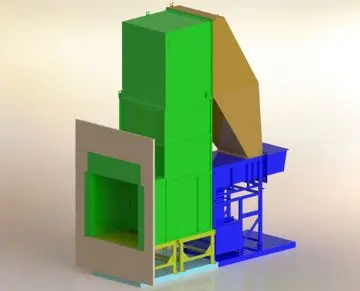

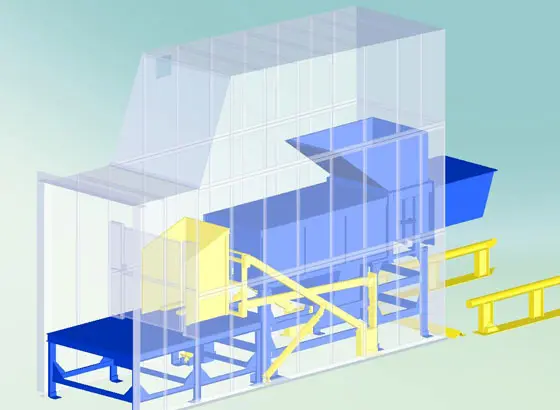

- Family of Stationary Compactors engineered for efficiency and reduce spillage

- Self-contained Roll-off Compactors ideal for low- to mid-volume plants with limited space

- All-Electric Elevated Bulk Loaders to replace the use of hydraulics and load-thru roofs to eliminate spillage

- Mobile Packer/Front Loaders ideal for small volume plants needing economical alternatives to landfill options

Options Designed For Your Needs

Every ReConserve waste removal system is custom designed and professionally engineered from start to finish. Our goal is to provide you with options that meet your specific needs and space requirements. All OSHA guidelines are met or exceeded in our solutions.

Contact Our Team:

To find out more about our advanced food waste removal systems and how we can benefit your operations, contact our Bakery Services team:

Joe Douglas

Vice President Bakery Services - South

770-967-0145 x107

jdouglas@reconserve.com

John Hawrylko

Vice President Bakery Services -

North

732-558-2554

jhawrylko@reconserve.com

Kevin Shore

Vice President Bakery Services - West

559-799-7390

kshore@reconserve.com

Adam Cowan

Senior Vice President

ReConserve, Inc.

310-458-1574 x253

acowan@reconserve.com

Thomas O'Rourke

Manager Bakery Services -

Upper Midwest

612-308-0257

torourke@reconserve.com

Stan Wilson

Manager Bakery Services -

South Central

901-422-1081

swilson@reconserve.com

Craig Burrell

Manager Bakery Services -

Eastern Midwest

567-271-1314

cburrell@reconserve.com

Jeff Weber

Manager Bakery Services -

Lower Midwest

913-426-5053

jweber@reconserve.com

Rodger Wilson

Vice President of Bakery Services for the Great Lakes

708-259-0298

rwilson@reconserve.com

Stationary Compactor Systems

Stationary Compactor Systems